Have an opportunity to add to this list? Email ARCHITECT editor Wanda Lau.

As we look ahead to months of social distancing, not to mention the incomprehensible turmoil the COVID-19 pandemic will have on human life as well as the economy, it’s easy to feel overwhelmed with a sense of helplessness. But now, more than ever, the world needs legions of volunteers to offer their technical expertise, manual labor to address gaps in the supply chain, and compassion to assist those in need, and particularly medical personnel of the front lines of fighting the coronavirus.

“What architects are good at are being collaborators and problem-solvers because they have to take information from all these constituents and put together a plan of action,” says Jonathan Kinsley, director of marketing and a senior associate at New York–based Handel Architects. “The better of them are able to speak truth to power: They have an idea and then follow through on it without getting mired in the bureaucracy.”

If you have the urge to take action, from fabrication to teaching to donating funds, below are some initiatives seeking volunteers and help that are particularly suited to architects, designers, and AEC professionals and students. (In addition to the firms and institutions listed below, consider donating to international, national, and local organizations that could use the support at this time, from the COVID-19 Solidarity Response Fund to your neighborhood food pantry.)

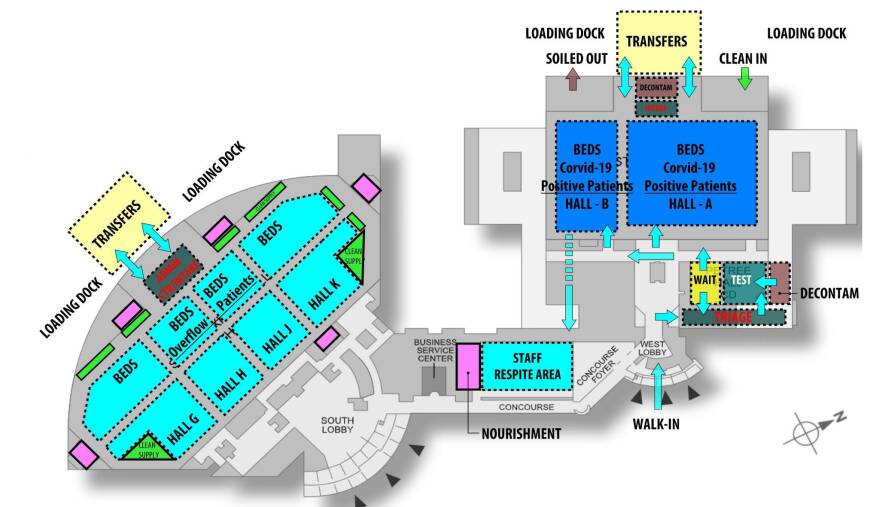

1. Construct Health Care Infrastructure

Architects and firms with health care expertise are needed to consult on the adaptation of existing spaces—schools, hotels, gymnasiums—or build temporary structures to handle the influx of COVID-19 patients, as discussed in ARCHITECT’s article “These Architects Are Addressing COVID-19 Health Care Infrastructure Capacity.” National and statewide disaster response efforts are in motion to coordinate the conversion and construction of these facilities.

To help with the Federal Emergency Management Agency and U.S. Army Corps of Engineers, which are overseeing these efforts, register at the federal government’s System for Award Management website; there, you can also add your company to the Disaster Response Registry. Those who have received training in the AIA Safety Assessment Program (SAP) can “also rely upon the chain of command in the National Response Framework through to your state,” according to AIA’s Disaster Assistance Program. Check in with your local or regional AIA components, as many, including AIA Columbus and AIA Maryland, are gathering design contacts to send to state and local leaders. Or contribute to the national AIA's online platform for sharing research and information on COVID-19 alternative health care sites.

2. Put Your 3D Printer and Laser Cutter to Use

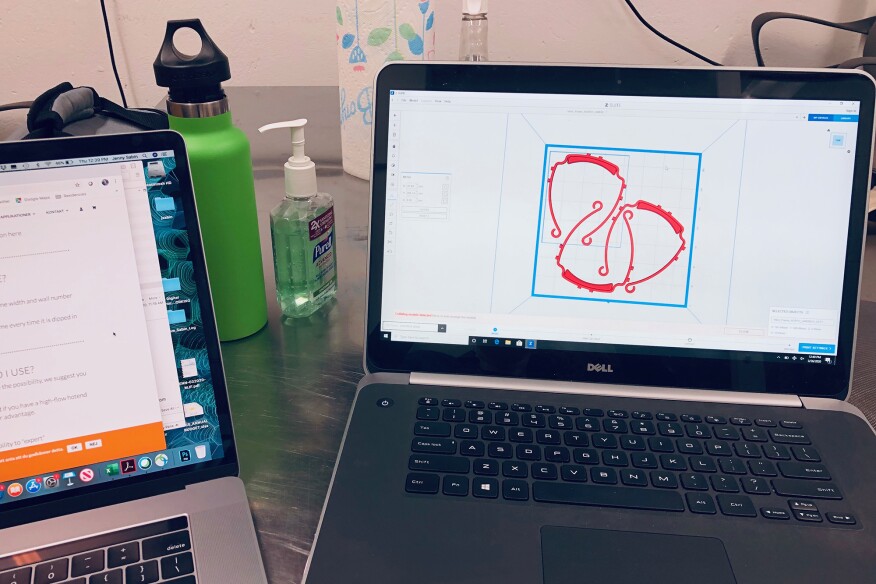

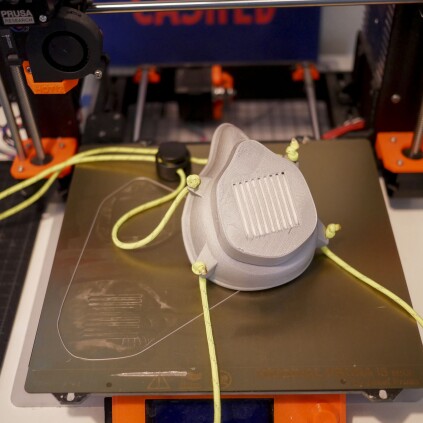

Digital fabrication networks and maker communities across the country have lit up in response to the dire shortage of personal protection equipment (PPE) for health care personnel. The collaborations often involve medical campuses, architecture schools, and design practices with available—and idle—advanced manufacturing equipment and an inventory of 3D printing medium, polyethylene sheets, PET, PLA, and ABS. A number of initiatives are welcoming volunteers of all skills and manufacturing capacities. “One 3D printer isn't going to make a big difference, but within the informal, democratic, bottom-up network of multiple printers and people coming together, we [can] deliver thousands of shields,” says Jenny Sabin, architecture professor and the associate dean for design initiatives at Cornell University College of Architecture, Art, and Planning (AAP). “There's a sense of urgency, but also people realizing that they can contribute, help, and get right to it.”

Operation PPE at AAP arose when Kirstin Petersen, an assistant professor in Cornell College of Engineering, asked Sabin if she and AAP could help respond to Weill Cornell Medicine’s urgent request for PPE face shields. By the next morning, Sabin tells ARCHITECT, she had received approval from Cornell AAP dean J. Meejin Yoon, AIA, and the director of facilities to reopen AAP’s digital fabrication lab, which had been closed along with the rest of the campus, and had it back in operation along with her eponymous studio’s fab lab. The university’s department of computer science, school of mechanical engineering, and other fabrication labs across campus quickly joined the effort to laser cut face shields and 3D print visors, using a file originally designed by 3D Verkstan and tested and verified by Weill, Sabin adds. “The polyethylene sheet can either be sanitized for re-use or tossed and a new one clipped on to the visor,” she explains. “For the visor, Weill requested PET or PETG material as it has a higher melting point, and the PETG material can be sanitized under [ultraviolet light]. However, they are taking PLA and ABS printing material too.”

AAP’s alumni network not only joined the printing effort, but also reached out to their networks. Handel Architects associate and model shop manager Charles Thornton put out a call to an email list of 40-plus shop managers that was previously assembled to exchange group tours of their fabrication facilities. Many firms, including KPF, Bjarke Ingels Group (BIG), Grimshaw Architects, and Terreform ONE, immediately jumped into action.

To date, more than 5,800 PPE parts have been delivered to New York City, where Weill sanitizes them and distributes them to health care professionals. “While our 'rapid' prototyping machines are not meant for industrial-scale manufacturing, and by those standards are not ‘rapid,’ ” acknowledges Yoon, “as industry ramps up, our distributed maker capabilities can fill this essential gap to help those on the front lines of the COVID-19 health care crisis.” Sign up to participate in Operation PPE here.

Through the coalition of makers and health care workers NYC Makes PPE, you can also donate funds to help procure PPE for production. Organizations represented in the coalition include Weill, Columbia University Makerspace, and SHoP Architects.

At the University of Southern California School of Architecture, director of graduate and post-professional architecture Alvin Huang, AIA, put out a call to USC faculty and staff this past weekend and was immediately flooded with offers to help from 69 people with 85 3D printers, three laser cutters, and 200-plus spools of filament—and counting. The SoA is working with the university’s Viterbi School of Engineering, Keck School of Medicine, and Iovine and Young Academy to 3D print an N95 mask approved by Keck, as well as an approved face shield design, Huang tells ARCHITECT. His team currently needs help locating sheets of 0.02-inch-thick PETG for the face shields. Firms that have joined this effort include Arup, CO Architects, Brooks + Scarpa, Michael Maltzan Architects, and Huang’s own practice, Synthesis Design + Architecture. The Keck School is coordinating pick-ups and distribution to area hospitals. “We are also working with [chief design office for the city of Los Angeles] Christopher Hawthorne … who is trying to make this a citywide effort,” Huang adds. Sign up here to help. Huang will reach out with details.

Similar efforts to produce PPE and other medical equipment are ramping up or underway at the Massachusetts Institute of Technology, Michigan State University, the University of Michigan, the University of Kentucky, Yale University, and the Rhode Island School of Design. Search online if your alma mater or local institution is coordinating an effort, or join one mentioned above.

Labs across campus respond to a call; MIT sends thousands of items directly to area hospitals in need. #OneMIT @SustainableMIT https://t.co/yMzMBUuPTn pic.twitter.com/A3YP74UF5m

— MIT Students (@MITstudents) March 30, 2020

3. Raid Your Office for Supplies

If your firm’s fabrication shop is closed, such as the case for Handel Architects, you can always take a quick look in the stockroom for PPE available for donation. For example, Handel’s Kinsley said the firm found 40 N95 masks purchased for protection during spray painting. “[G]etting the word out to have someone to go back to office and source and distribute them would be helpful. Other industries that have these that may not realize they have a backlog of these sitting in their inventory that could be tapped."

Forty isn’t much, but in this era of emergency, ad hoc supply chains, having something is better than the alternative. “It’s a little bit ridiculous that we have to be doing this,” Kinsley says ruefully, “but that’s what the need is.”

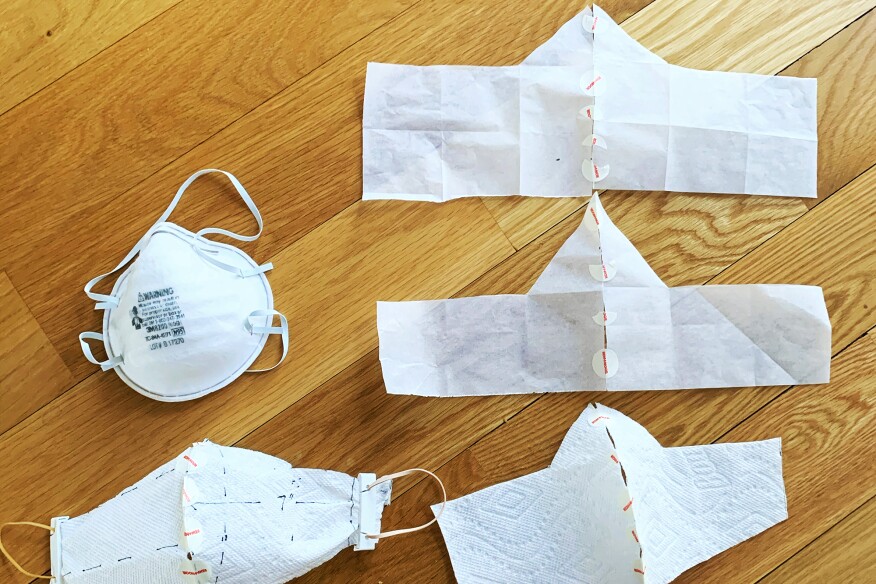

4. Sew Masks En Masse

Do-it-yourself instructions for sewing cloth masks for medical professionals as well as for yourself are popping up across the internet. Global firm CannonDesign has formed a coalition of designers and makers, including the SUNY Buffalo School of Architecture and Planning, MaterialsIn, Oxford Pennant, Stitch Buffalo, and the Factory Buffalo, to ideate an easier DIY sewing pattern that can be adjustable per wearer via 3D printed clips. A prototype was finished as of this week, says CannonDesign principal Michael Tunkey, AIA. The cloth masks won’t stop a virus, he acknowledges, but they can be worn over an N95 mask to extend its life, and help keep the sneeze of a knowingly or unknowingly infected person from infecting someone else.

Tunkey says that the final prototype for the mask comprises two parts: a cloth that can be cut and sewn by hobby sewists in 10 to 15 minutes, and 3D-printed clips that can be made in under a minute, thanks to an innovation from SUNY Buffalo, which brought the manufacturing time down from an hour per pair. “We anticipate Evergreen Health in Buffalo will have nearly 300 masks this Saturday,” Tunkey says, which includes the donation of 100 masks by Fisher-Price. “Our research committee is going to collect feedback from them over two to three days as another beta test. If the feedback is strong, we’ll then try and scale significantly” by building partnerships. “We already have 103 volunteers without even really asking for help,” he adds. CannonDesign is also in talks with corporations with commercial sewing operations. Sign up to help here.

.

5. Teach—and Learn from—Your Design Community and Beyond

Have some knowledge that you want to share from the safety of your own house? Volunteer to provide virtual tutorials and demonstrations of your skills in Grasshopper, Python, and more via YourDesk University on YouTube Live. The initiative arose when Timon Hazell, a Washington, D.C.–based associate and senior technical designer at Walter P. Moore, and his colleagues were thinking of new ways to “truly love their neighbor [at a time when] it’s hard to go out and help people out,” he tells ARCHITECT. “Conferences were being cancelled [and] people are scared for their job. Now is the supreme time to learn those things that people had been pushing off, [so] what if we could use our connections … to gather a following of people to share their expertise?”

In nine days, he and his collaborators created a website, tested streaming methods, and sent out speaker invitations. They veered away from basic tutorials that already exist online as well as “direct marketing topics and sales-heavy presentations,” he says. “The initial focus is on digital exploration, data visualization, machine learning, virtual and augmented reality, visual programming, and how some of the more advanced companies have implemented their ‘digital revolutions’ on a broad scale.” Sustainability and resiliency are also on the to-do list.

The current lineup features presenters from SmithGroup, Hypar, Gensler, and NBBJ, and covers topics that include face-shield production, information management, cultivating a tech community, and scripting. Sign up here to propose a course. Include a brief description of your topic and whom you have in mind as co-presenters or panelists.

AEC Experts from all across the US have been gathering together under the "YourDesk University" Banner to bring you LIVE innovation focused training. Tune in 2-3x weekly for amazing tutorials and panel discussions. https://t.co/2wXaYJabTn #DynamoBIM #Grasshopper #AEC #VDC #BIM pic.twitter.com/7djUT48nT4

— Timon Hazell (@TmnHzll) April 2, 2020

.

More than 10,000 high school students and 4,100 architecture, engineering, and construction mentors were engaged in the ACE Mentor Program of America when the coronavirus changed life as we know it. The program pairs high school students with AEC professionals for a semester or full academic year to teach them firsthand about the building profession through presentations, hands-on activities and training, and a capstone project. In the past two weeks, ACE president Diana Eidenshink has helped its 74 affiliates—many of which operate in major cities with underserved communities— transition to a virtual curriculum schedule, “We’ve cut 300 licenses from GoToMeeting,” she says, and accelerated the release of an interactive online resource for students.

Though some programs were canceled for the remainder of the academic year, Eidenshink is always looking for professionals to serve as future mentors and donors to support the program’s scholarships and operational expenses, such as background checks. Three years ago, the organization realized many ACE alumni needed support post-graduation, and revamped its strategic plan to focus also on internships, support through college, alumni support, and summer programs. As a result, the organization is looking for internship opportunities for high school and college students, Eidenshink says. “Our ultimate goal is to give these kids a successful path into the workforce and backfill the need that the construction industry has.”

The application process for mentors typically opens in August, but you can get on the waitlist now. Eidenshink says the average tenure of a mentor is five to seven years. Interested individuals and firms can email [email protected], or donate to ACE here.

6. Help Keep Your Business and Others Running

If you suspect your office will be operating remotely for some time and are worried about keeping its doors open, share your concerns on the living document “Covid 19 Architecture Firm Best Practices, Communications, and Policies.” Put together by Evelyn Lee, AIA, Slack Technologies senior experience designer, Practice of Architecture founder, and ARCHITECT contributor, along with Apostrophe Consulting founder Je’Nen Chastain, Assoc. AIA, the guide aggregates best practices for firms of all sizes on maintaining business continuity, crafting office policy, employee communications, managing remote teams, and working remotely. Lee and Chastain are looking for contributors, feedback, and additional topics to cover. To add to the discussion, send an email to Lee. Her email address is provided in the guide’s introduction.

7. Consider Yourself More of a Tech Company? Read On ...

The state of New York is looking for technology companies, nonprofits, research labs, universities, and other organizations to form a Technology SWAT team and help respond to urgent COVID-19 needs. “We have a particular need for professionals with experience in product management, software development / engineering, hardware deployment & end-user support, data science, operations management, design, or other similar areas,” the website states. Sign up to volunteer for a SWAT Team here.

Email us with info about your recipient at [email protected]! We can ship nationally and will surprise as many of your loved ones as we can. Please note that we cannot handle customized care packages at this time, but we promise much joy and love in each shipment 💕 pic.twitter.com/8ZEPFDnNVG

— Coolhaus (@COOLHAUS) March 30, 2020

8. Send a Sweet Treat

A lighthearted ending to this story: Surprise a loved one with an ice cream care package complimentary of Coolhaus, an ice cream and frozen dessert brand founded by Natasha Case and Freya Estreller, who formerly worked in architecture and real estate development. While you’re emailing the company with your intended recipient, consider supporting the women-led and -founded firm with a cool purchase.

This story has been updated since first publication.

To receive our latest coverage of COVID-19 in your inbox, subscribe to ARCHITECT newsletters.