At the Brisbane, Australia, campus of the University of Queensland, 237,000 square feet of new construction was recently completed on the Advanced Engineering Building (AEB). Designed collaboratively by local firms Hassell and Richard Kirk Architect, the facility is a hands-on learning site for its students and faculty with classrooms, large-scale manufacturing and civil engineering research labs, and passive design features with real-time monitoring of the AEB’s structural and climate performance.

“Students will be able to learn from the latest in sustainable technology in this building, which is designed to achieve a 40-percent reduction in annual energy performance and can be naturally ventilated 183 days of the year,” says architect Richard Kirk, principal of his eponymous firm. The subtropical climate of Australia’s eastern coast makes sustainable features such as solar shading, controlled daylighting, and a naturally ventilated building envelope economically feasible. And glulam timber applications in the façade and roof trusses of the building’s main auditorium highlight local materials that contribute to the AEB’s sustainability story.

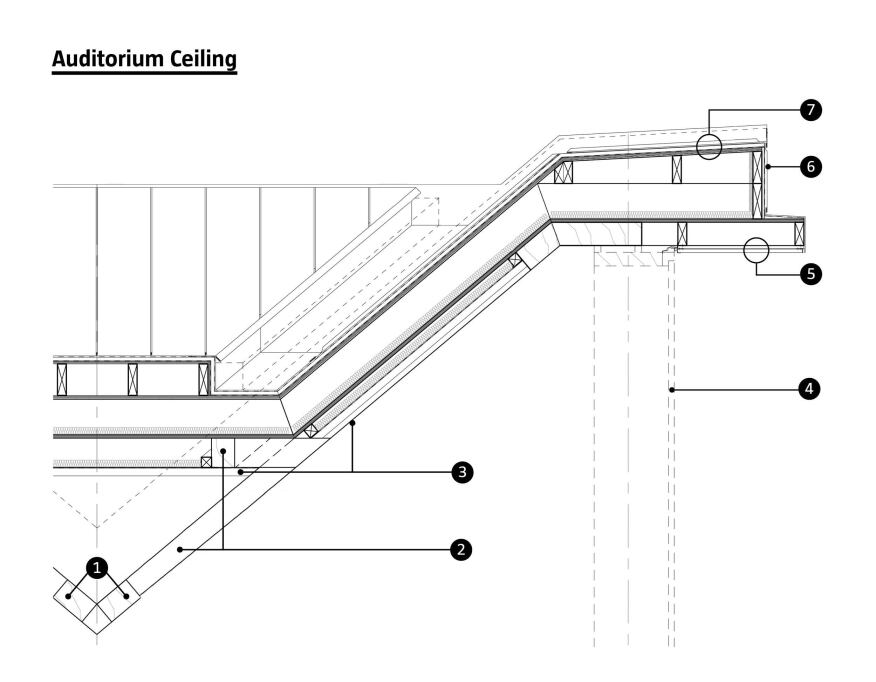

The three-story, 500-seat GHD Auditorium is enclosed in glass on two sides, connecting inhabitants with views over a lake that is a model of biodiversity . The interior is finished in local timber to provide visual warmth and, along with custom-designed acoustic glass reflectors, an acoustic quality that transmits sound without electric amplification. Supporting the 3,000-metric-ton (6.6 million-pound) roof are trusses constructed from local hardwood species formed into glulam, manufactured by Hyne Timber 160 miles up the coast in the city of Maryborough. The trusses run to lengths of 82 feet and measure between 13 and 16 feet tall, depending on each truss’s location along the accordion-style roof. Chord members are constructed from glulam beams made from local hardwoods measuring 2-1/2 to 3-1/3 inches wide. The beams are laminated together and fastened with slotted steel plates and exposed steel bolts. To reduce acoustic echoing, a series of 1-1/2- by 3/4- inch wood strips planed on all sides bridge the space between trusses.

The design optimizes acoustic performance while demonstrating the versatility of timber as a large-scale load-bearing element. “As the home of engineering at the University of Queensland, the structural requirements for the roof were deliberately exposed and expressed in an interesting and evocative way,” says Mark Loughnan, principal at Hassell. To maintain uncluttered views of the roof’s structure, the trusses were treated with a clear, fire-retardant paint that eliminates the need for a sprinkler system.

The auditorium’s other surfaces are also finished in local varieties of wood. Joinery made of Rosewood—a termite-resistant species—frames internal windows, doors, and walls. More than 13,000 feet of flooring is constructed from recycled Eucalyptus pilularis. Commonly referred to as blackbutt, this local hardwood can withstand heavy foot traffic. The walls are also sheathed in blackbutt paneling.

The size and weight of the roofing system required special considerations for installation. The trusses were prefabricated off site and then broken down to be transported to the university on 18-wheelers. The trusses were then reassembled at ground height with 1-inch galvanized steel bolts grouped with 16mm steel plate cleats and boxes and 5mm-thick washers. The completed structure was hoisted up over two concrete walls by two large cranes.

The building opened to the university in 2014 and has received the Sir Zelman Cowen Award for Public Architecture, the Emil Sodersten Award for Interior Architecture, and a National Award for Sustainable Architecture, all from the Australian Institute of Architects’ 2014 National Architecture Awards.

“The use of local Queensland timber became central to developing sustainability initiatives beyond the singular energy strategies typically targeted in large projects,” says Hassell’s Loughnan. “The legacy of the project is to demonstrate the potential for innovation beyond the current established targets and promote an underused, but inherently sustainable, local industry.”

Note: The original version of this story misspelled the name of Hassell's Mark Loughnan. We regret the error.